Protecting Pharma Integrity Through Reliable 3PL Solutions

Singapore stands as a leading hub for pharmaceutical manufacturing and global distribution. However, maintaining the efficacy of temperature-sensitive products such as vaccines, biologics, and medical samples remains a major operational challenge.

To meet strict regulatory requirements and ensure product safety, pharma companies are increasingly partnering with trusted 3PL providers in Singapore like MAK Logistic. Through advanced temperature-controlled solutions, these partnerships safeguard cold chain integrity and guarantee compliant, seamless deliveries.

1. Ensuring Stringent Regulatory Compliance (HSA & GDP Standards)

The Health Sciences Authority (HSA) enforces rigorous guidelines for storing and transporting pharmaceuticals in Singapore.

A qualified 3PL provider in Singapore ensures full adherence to Good Distribution Practice (GDP) standards — vital for protecting pharmaceutical quality and patient safety. These practices are also aligned with the World Health Organization’s GDP guidelines to ensure global compliance and quality assurance.

How MAK Logistic ensures compliance:

- Certified Facilities: Our temperature-controlled warehouses comply with WHO and EMA standards, ensuring traceability and contamination prevention.

- Validated Systems: HSA-compliant procedures, staff training, and audits uphold international quality benchmarks.

Partnering with a GDP-certified 3PL partner helps pharma companies eliminate compliance risks while maintaining consistent quality.

2. Specialized Cold Chain Infrastructure for Every Temperature Range

Modern pharmaceutical products require different temperature zones throughout the supply chain. From vaccines to biologics, maintaining precise temperatures is essential for product quality and regulatory compliance.

MAK Logistic’s 3PL solutions in Singapore provide end-to-end cold chain infrastructure — helping clients avoid costly in-house investments while ensuring world-class cold chain performance. As Singapore continues to strengthen its logistics ecosystem, the evolution of the nation’s cold chain industry has played a key role in supporting the growing pharmaceutical and life sciences sectors.

According to Enterprise Singapore, the city-state’s logistics sector continues to innovate through smart warehousing, IoT integration, and advanced temperature management — critical for maintaining Singapore’s global reputation as a pharma logistics hub.

Our capabilities include:

- Multi-Temperature Handling: Refrigerated (2°C–8°C), frozen (–20°C), and ultra-cold (–70°C) solutions tailored to pharmaceuticals.

- Real-Time Monitoring: IoT-enabled sensors and GPS tracking provide continuous visibility and immediate alerts during transit.

- Secure Handover Points: Seamless transitions between air, sea, and road transport maintain an unbroken cold chain.

This advanced infrastructure ensures that temperature-sensitive products remain stable, compliant, and protected at every stage of the journey.

3. Risk Mitigation and Unbroken Product Integrity

In pharmaceutical logistics, even small temperature deviations can result in product loss or regulatory breaches.

MAK Logistic minimizes these risks through precision monitoring and contingency planning.

Our risk management approach:

- Unbroken Cold Chain: Guaranteed continuity across multi-stage and cross-border deliveries.

- Contingency Planning: Backup systems, alternate routes, and power redundancies.

- Continuous Auditing: Regular equipment checks and data validation to ensure reliability.

With this proactive approach, pharma companies can maintain product integrity and protect brand trust.

4. Operational Efficiency and Cost Optimization

Maintaining a compliant cold chain internally is resource-heavy. Outsourcing to a reliable 3PL provider in Singapore enables pharma companies to focus on R&D and production while optimizing logistics costs.

Key benefits:

- Scalability: Adjust logistics capacity based on demand or new product launches.

- Faster Market Reach: Optimized routes for timely distribution across Singapore and Malaysia.

- Cost Savings: Shared infrastructure reduces capital expenditure and workforce needs.

MAK Logistic delivers efficient, secure, and compliant 3PL operations that drive long-term value.

5. Advanced Handling, Packaging, and Value-Added Services

Temperature control is only part of the equation. Pharmaceutical logistics also demands specialized handling, packaging, and coordination to ensure every product arrives safely and compliantly.

MAK Logistic’s advanced 3PL solutions include:

- Phase Change Materials (PCM) and Vacuum Insulation Panels (VIPs) for stable temperature control.

- Kitting, relabeling, and repackaging to meet diverse market regulations.

- Inventory and distribution management systems for complete stock visibility.

These value-added services make your pharma supply chain faster, smarter, and fully compliant. To explore how these specialized services enhance efficiency and compliance, check out our detailed blog on Value-Added Warehouse Services in Singapore.

6. Seamless Cross-Border Deliveries: Singapore to Malaysia

As part of its regional network, MAK Logistic offers cross-border road freight solutions from Singapore to Malaysia.

With temperature-controlled fleets, customs expertise, and continuous tracking, we ensure products maintain stability and compliance throughout the journey — making regional distribution smooth and cost-effective.

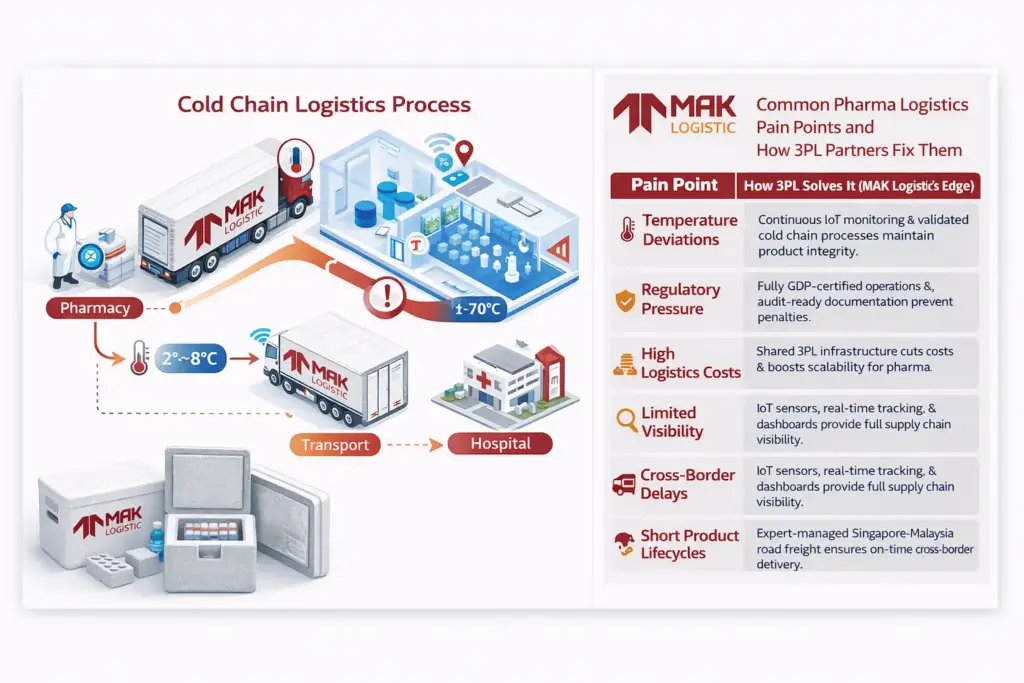

Common Pharma Logistics Pain Points and How 3PL Partners Fix Them

Pharmaceutical companies in Singapore face multiple challenges in maintaining product quality, compliance, and visibility. Here are the most common pain points — and how a trusted 3PL partner like MAK Logistic provides effective solutions.

| Pain Point | Challenges Faced by Pharma Companies | How 3PL Solves It (MAK Logistic’s Edge) |

| Temperature Deviations | Product spoilage and loss of efficacy due to fluctuating temperatures. | Continuous IoT monitoring and validated cold-chain processes ensure integrity. |

| Regulatory Pressure | Non-compliance penalties and shipment delays due to strict HSA & GDP standards. | Fully GDP-certified operations and audit-ready documentation. |

| High Logistics Costs | Expensive in-house cold chain infrastructure and workforce. | Shared 3PL resources lower costs and increase scalability. |

| Limited Visibility | Lack of transparency during transit causes uncertainty. | Real-time tracking, alerts, and digital dashboards enhance visibility. |

| Cross-Border Delays | Customs bottlenecks and potential temperature breaks. | Expert-managed Singapore–Malaysia road freight ensures smooth transit. |

| Short Product Lifecycles | Expiring or delayed medicines reduce efficiency. | Smart warehousing and demand-based inventory flow prevent waste. |

By addressing these critical challenges, MAK Logistic empowers pharma companies to maintain compliance, optimize operations, and achieve reliable temperature-controlled deliveries across Singapore and Malaysia.

Conclusion: Your Trusted 3PL Partner for Pharma Logistics in Singapore

In the pharmaceutical world, every degree and every hour counts. That’s why partnering with a trusted 3PL provider in Singapore like MAK Logistic is key to ensuring quality, compliance, and customer confidence.

Why pharma companies trust MAK Logistic:

✅ Advanced cold chain technology

✅ HSA- and GDP-compliant operations

✅ Scalable, cost-efficient 3PL solutions

✅ Cross-border expertise between Singapore and Malaysia

With MAK Logistic, your pharmaceutical products are delivered safely, compliantly, and on time — every time.